Why Is EMC So Important When Working With Electronics?

5 min read

Why Is EMC So Important When Working With Electronics?

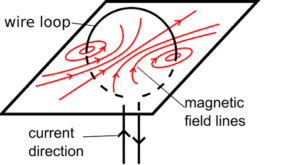

When it comes to electronics, electromagnetic compatibility (EMC) is one of the most important considerations. If electronic equipment is not designed and built with EMC, it can cause all sorts of problems, from interference with other equipment to complete system failure. To ensure that your electronic devices work properly and without interference, you must ensure that they comply with the relevant EMC standards.

If you are designing or manufacturing electronic equipment, you need to be aware of the EMC importance and make sure that your products comply with the relevant standards. Here are some of the reasons why EMC is so important:

1. To Avoid Interference

One of the main reasons why EMC is so important is to avoid interference. Interference can cause problems, from degradation in signal quality to complete system failure. It is important to ensure that your electronic equipment is designed and built with EMC in mind to prevent interference.

It would help if you made sure your electronic equipment is placed as far away from other electronic equipment as possible. If you cannot avoid placing your equipment near other electronic equipment, you must ensure it is adequately shielded. You can also find an EMC Testing lab to test your products before you release them to the market. Also, keep your electronic equipment away from sources of electromagnetic radiation, such as microwaves and power lines.

2. To Comply With Regulations

To sell electronic equipment in many parts of the world, you need to ensure that it complies with the relevant electromagnetic compatibility (EMC) regulations. These regulations are implemented to ensure that electronic equipment does not cause interference with other equipment or systems. If your electronic equipment does not comply with the rules, you may face fines or even have your equipment seized.

There are several different EMC regulations worldwide, so ensuring that your products comply with all of them is vital. In Europe, the main regulatory body is the European Union Agency for Network and Information Security (ENISA). ENISA has published several standards covering various electronic equipment, from information and communication technology (ICT) systems to medical devices. ENISA also publishes guidelines on testing and certifying ICT systems for compliance with its standards.

In North America, the main regulatory body is the Federal Communications Commission (FCC). The FCC has published several rules covering various electronic equipment, from home appliances such as microwaves and televisions to industrial control systems. The FCC also has a certification program for manufacturers of electronic equipment.

3. To Improve Performance

In many cases, the design of electronic equipment can be improved by considering EMC. For example, suppose you are designing a system that will be used in an industrial environment. In that case, you need to ensure that it can withstand the high levels of electromagnetic radiation often present in such environments.

By ensuring that your electronic equipment is designed for EMC, you can improve its performance and avoid problems caused by interference. If you are having trouble with interference or other compatibility issues, consult an EMC engineer to help you design a system compliant with the relevant standards.

4. To Protect Against Damage

Electromagnetic compatibility is not just about avoiding interference but also about protecting electronic equipment from damage. High levels of electromagnetic radiation can cause physical damage to electronic components, leading to system failures.

When designing your electronic equipment, use quality materials that can protect against electromagnetic radiation. Also, design your equipment according to the relevant EMC standards. This will help ensure that your equipment complies with the relevant regulations and is less likely to suffer from damage caused by electromagnetic radiation.

5. To Ensure Safety

In some cases, electronic equipment can emit harmful levels of electromagnetic radiation. This can be a serious health hazard, so it is crucial to make sure that your equipment is designed and built with safety in mind. Several international safety standards cover the emission of electromagnetic radiation from electronic equipment. Make sure

One of the best ways to improve performance is to ensure that your equipment is well-maintained and up-to-date. Ensure that all of your software is up-to-date and that you have the latest drivers for your hardware. Also, keep your hardware clean and free from dust and dirt.

6. To Reduce Costs

There are many reasons why you might want to reduce the costs of your electronic equipment. Maybe you need to save money on your electric bill, or perhaps you need to free up some extra cash to invest in new equipment. Whatever the reason, there are several ways you can reduce the costs of your electronic equipment.

One of the best ways to reduce costs is to ensure that your equipment is well-maintained and up-to-date. Ensure that all of your software is up-to-date and that you have the latest drivers for your hardware. Also, keep your hardware clean and free from dust and dirt.

You can also reduce costs by upgrading your equipment. If you have an old computer, it might be time to upgrade to a newer model. The same goes for other types of electronic equipment. If you’re using an old printer, upgrading to a newer model with better speed and the print quality might be time-consuming.

7. To Ensure Safety

Electromagnetic compatibility (EMC) is the ability of electronic equipment to operate properly in its environment without causing interference to other equipment or systems. EMC is a critical consideration for any electronic equipment, and several different regulations worldwide ensure that products are compliant. Compliance with EMC regulations can help improve performance, reduce costs, and ensure safety.

One of the main reasons why EMC is so important is because it helps ensure safety. If your electronic equipment causes interference with other equipment or systems, it could potentially cause dangerous situations. For example, if you’re using a power tool near other electronic equipment, the interference from the tool could cause the equipment to malfunction. This could potentially lead to injury or even death.

EMC is a critical consideration for any electronic equipment. There are several different regulations in place around the world to ensure that products are compliant. Compliance with EMC regulations can help improve performance, reduce costs, and ensure safety.