A check valve is the type of device that can only allow the flow of the waters in a single direction. They come with two ports. One acts as the inlet for the media, and one works as the press’s output. Because they allow the only media flow in one direction, they are also known as the one-way valves.

The primary purpose of this type of valve is to prevent the backflow in the system. There are still various things that many people do not know about. To provide you with your knowledge, we are here to tell you all about the check valve and its uses and functioning.

What Are Check Valves?

This type of valve depends on the pressure for different work. It needs a higher pressure on the input side of the check valve than the output side to open it. When the outlet side pressure is taller, the valve will close.

Depending on the type of valve, the closure mechanism will be different. Some valves do not need the handle, actuator, lever, or human to function appropriately. These are installed commonly in the application so that the backflow would become an issue.

However, as they are one-way valves, they are a cost-effective, efficient, and simple solution for solving the potential issue. Backflow can be an issue if it is contaminated and, therefore, contaminates the upstream of the media.

For instance, a sewer line will have a one-way valve to ensure that all the waste can go out, but with the re-enter system. You can also use it if the backflow causes damages to the equipment upstream, allowing media to flow in a single direction.

For instance, the reverse osmosis filter can only have the water pass through it in one direction. It is where the single-direction valve is needed to prevent this. The check valve manufacturer makes different sizes and types; other materials are used to ensure a check valve for every use.

Working Of Check Valve

Here is the basics of the working of the check valve:

Cracking Pressure

A check valve needs a minimum upstream pressure. It helps to open up the valve and lets it flow through it. This minimum upstream pressure in which the opening of the valve happens is known as the check valve cracking pressure. The particular pressure cracking changes based on the valve design and size. It helps ensure that the system can produce the cracking pressure and is appropriate for the application.

Closing

There is a various floating fish cage that uses the check valve as it helps with the water flow that allows us to change the water. The valve will close if the upstream pressure falls below the cracking pressure or backpressure.

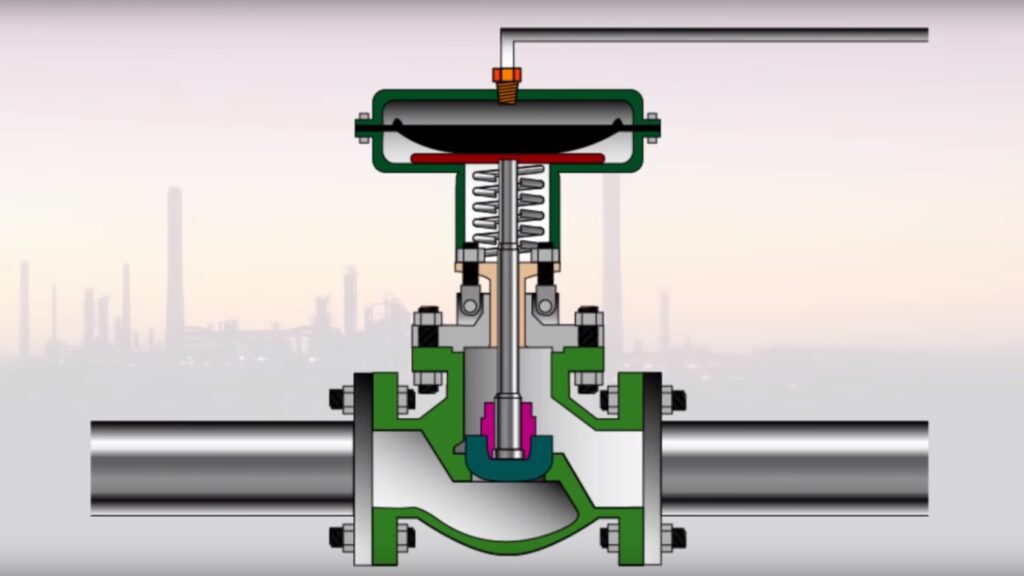

Depending on the design of the one-way valve, the closing mechanism can change. In other words, the backpressure pushes the ball, gate, diaphragm, or the disc valve against the orifice and seals it. Depending on the design, gravity or spring will assist the closing process.

Installation Orientation

Knowing the appropriate installation orientation is crucial as the one-way valve only works in a single direction. There are cases when there is an arrow on the valve housing for signaling the direction of the flow.

You will need to go through the valve to ensure it is installed in the intended flow direction. Flow cannot move via the system if the flow is backward, and the pressure build-up can cause damage.

Look At The Different Types Of Valves

Depending on the check valve design, it will work significantly differently. Below are some standard valve types that you will use for efficient working.

Spring Loaded Y

These valves tend to work similarly to the in-line spring-loaded check valves.

The difference is that the spring and movable disc will be positioned at a single angle. It will create the Y-shape. It is how it got its name. It operates the same as an in-line valve, but since the components are movable at an angle, they will be inspected and serviced while connected to the system.

Ball

The ball check valve uses the free-floating that will sit on the sealing seat for closing the orifice. The sealing seat will be conically tapered to guide the ball into the seat. It creates a positive seal that can help to stop the reverse flow.

When the fluid pressure in the inlet side exceeds the cracking pressure, the ball will be dislodged from the seat, which initiates the flow. When the pressure of the inlet does not go beyond the cracking pressure, there will be backpressure. There are also other types not included in this post.

Conclusion

These are the essential information that you should know about the check valve. There are various companies, such as YoonPak, that use these valve types to increase the efficiency of their business.